What is Metallurgical Corrosion and its Types

I. Introduction

A. Definition of Metallurgical Corrosion

Metallurgical corrosion refers to the deterioration of metals as a result of chemical reactions with the surrounding environment. This natural process can significantly impact the integrity of structures, machinery, and various metal components.

B. Importance of Understanding Metallurgical Corrosion

Understanding metallurgical corrosion is crucial for engineers, metallurgists, and anyone working with metal components. It allows for the development of effective preventive measures, ensuring the longevity and reliability of metal structures.

II. Types of Metallurgical Corrosion

A. Uniform Corrosion

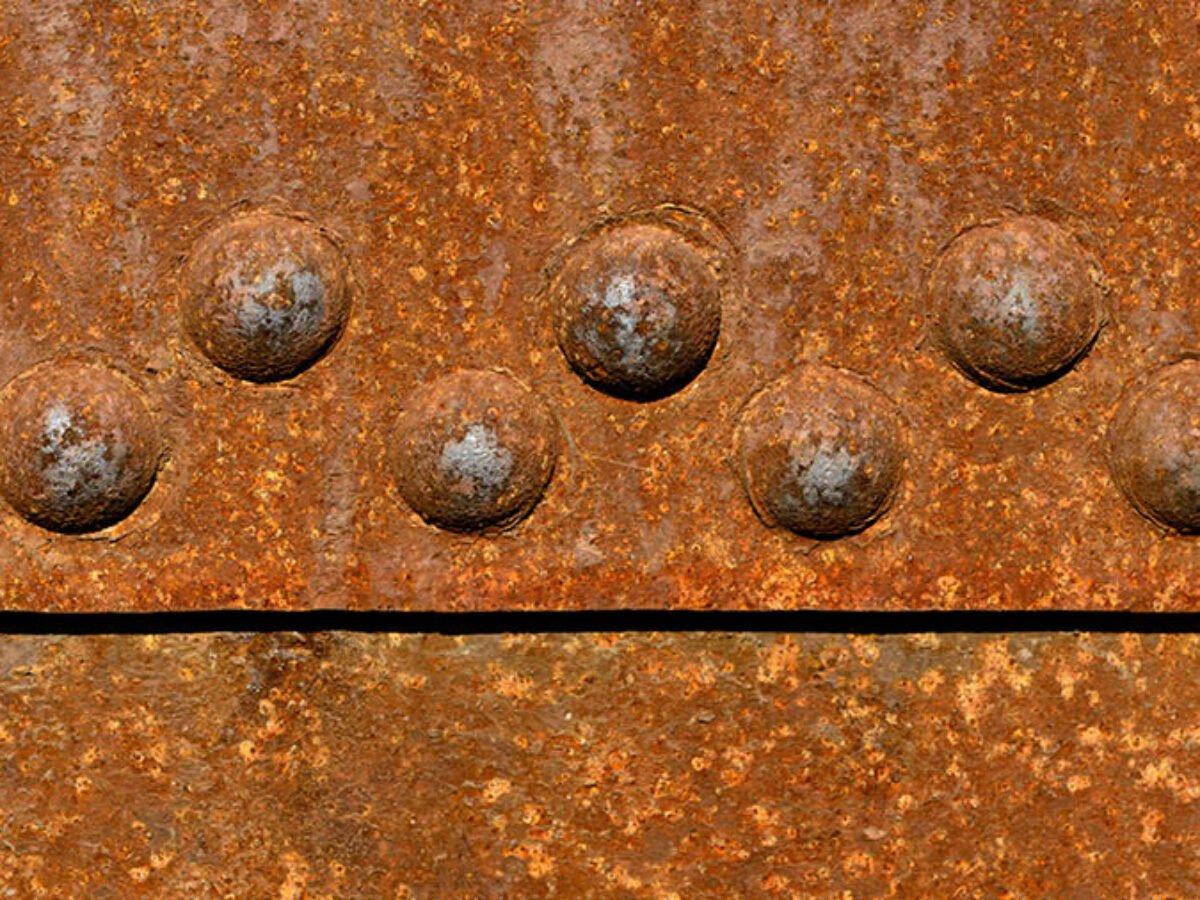

Uniform corrosion occurs evenly across the surface of a metal, leading to a gradual thinning of the material. It’s a common type of corrosion, often influenced by environmental factors such as moisture and oxygen.

B. Pitting Corrosion

Pitting corrosion involves localized damage, forming small pits on the metal surface. Despite its small size, pitting corrosion can lead to significant structural damage, particularly in critical components.

C. Crevice Corrosion

Crevice corrosion occurs in confined spaces, such as gaps and joints, where oxygen supply is limited. It poses a threat to structures with overlapping or closely connected metal parts.

D. Galvanic Corrosion

Galvanic corrosion results from the contact between two dissimilar metals in the presence of an electrolyte. This type of corrosion is common in industries where different metals are used in close proximity.

E. Stress Corrosion Cracking

Stress corrosion cracking is a form of deterioration caused by a combination of tensile stress and corrosive environments. It often occurs in alloys under constant stress, leading to crack formation.

F. Intergranular Corrosion

Intergranular corrosion targets the boundaries between metal grains, weakening the overall structure. This type of corrosion is influenced by the material composition and specific environmental conditions.

III. Factors Influencing Metallurgical Corrosion

A. Environmental Factors

The environment plays a crucial role in metallurgical corrosion. Exposure to moisture, humidity, and aggressive chemicals accelerates the corrosion process.

B. Material Composition

The composition of metals significantly influences their susceptibility to corrosion. Alloying elements can enhance or inhibit corrosion, making material selection a critical factor.

C. Temperature and Pressure

Extreme temperatures and pressures can accelerate corrosion processes. Understanding the operating conditions is essential for predicting and preventing metallurgical corrosion.

IV. Prevention and Control Measures

A. Protective Coatings

Applying protective coatings, such as paints or corrosion-resistant films, creates a barrier between the metal surface and the corrosive environment.

B. Corrosion Inhibitors

Chemical compounds can be used as corrosion inhibitors to slow down or prevent the corrosion process. These inhibitors form a protective layer on the metal surface.

C. Proper Material Selection

Choosing corrosion-resistant materials based on the intended application is crucial for preventing corrosion. This involves considering the environment and potential exposure to corrosive elements.

D. Cathodic Protection

Cathodic protection involves making the metal structure a cathode to prevent corrosion. This is often achieved through the use of sacrificial anodes or impressed current systems.

E. Regular Inspection and Maintenance

Frequent inspection and maintenance help identify early signs of corrosion, allowing for timely intervention and preventing extensive damage.

V. Real-life Examples

A. Case Study: Bridge Corrosion

Examining instances like bridge corrosion highlights the real-world impact of metallurgical corrosion on critical infrastructure. It emphasizes the importance of proactive corrosion management.

B. Industrial Applications

In industrial settings, metallurgical corrosion can affect equipment reliability. Implementing preventive measures is essential to ensure the efficiency and safety of industrial processes.

C. Corrosion in Maritime Structures

Metallurgical corrosion poses a significant threat to maritime structures due to exposure to saltwater. Proper corrosion control is vital for the durability of ships, offshore platforms, and port facilities.

VI. Importance of Addressing Metallurgical Corrosion

A. Economic Impact

Uncontrolled metallurgical corrosion leads to substantial economic losses. Investments in corrosion prevention and control measures prove cost-effective in the long run.

B. Safety Concerns

Corrosion compromises the structural integrity of various components, raising safety concerns. Addressing metallurgical corrosion is crucial to maintaining a secure working environment.

C. Environmental Consequences

Metallurgical corrosion can result in the release of harmful substances into the environment. Preventing corrosion minimizes the ecological impact and promotes environmental sustainability.

VII. Conclusion

In conclusion, understanding metallurgical corrosion and its various types is essential for preserving the integrity of metal structures. From uniform corrosion to stress corrosion cracking, each type demands specific preventive measures. By addressing factors such as environmental conditions and material composition, industries can proactively manage and mitigate the impact of corrosion. It’s not just about protecting assets; it’s about ensuring safety, economic efficiency, and environmental responsibility.