MATERIALS OF FUTURE

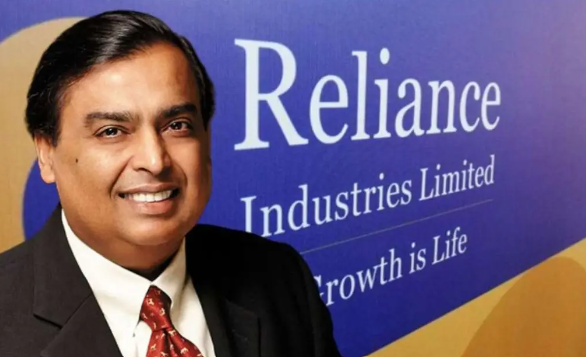

Indian conglomerate Reliance Industries’ Chairman Mukesh Ambani Announces India’s First Carbon Fiber Facility in Gujarat

Why Carbon fiber can be material of the Future?

Carbon fiber is a lightweight, high-strength material known for its exceptional stiffness, durability, and resistance to corrosion. It is composed of thin, strong crystalline filaments of carbon atoms, which are bound together with a polymer matrix, typically epoxy. The resulting composite material exhibits a combination of properties that make it suitable for various applications in industries such as aerospace, automotive, sports equipment, and more.

Here are some key characteristics and properties of carbon fiber:

👉 High Strength-to-Weight Ratio: Carbon fiber composites are incredibly strong for their weight, making them ideal for applications where strength and low weight are critical, such as aircraft and high-performance sports equipment.

👉Low Density: Carbon fiber is lightweight, which contributes to its high strength-to-weight ratio. This property is advantageous in applications where minimizing weight is essential, such as in the aerospace and automotive industries.

👉 Stiffness: Carbon fiber composites have high stiffness or rigidity, providing structural integrity and stability. This makes them suitable for applications where minimal deflection is important, such as in high-performance sports equipment and structural components.

👉 Corrosion Resistance: Unlike metals, carbon fiber does not corrode. This makes it an attractive choice for applications in harsh environments or where exposure to moisture and chemicals is a concern.

👉 Temperature Resistance: Carbon fiber composites can withstand high temperatures, making them suitable for applications in environments with elevated heat, such as in aerospace and motorsports.

👉 Electrical Conductivity: Carbon fiber is electrically conductive. However, the degree of conductivity can vary depending on the specific type of carbon fiber and its manufacturing process.

👉 Design Flexibility: Carbon fiber can be molded into complex shapes, providing designers with flexibility in creating intricate and aerodynamic structures. This is particularly beneficial in the aerospace and automotive industries.

👉 Aesthetics: Carbon fiber has a distinctive woven appearance that many people find aesthetically appealing. This visual characteristic is often exploited in high-end sports equipment, automotive components, and consumer goods.

Despite its numerous advantages, carbon fiber also has some limitations, such as its relatively high cost and susceptibility to impact damage. Nonetheless, ongoing research and technological advancements aim to address these challenges and further expand the range of applications for this remarkable material.